Originating from ship desulfurization systems, ZEME has steadfastly upheld the principles of customer service and innovative dedication. Today, the company stands as a leading Engineering, Procurement, and Construction (EPC) contractor in the field of marine desulfurization systems, holding the top position in the global market share and over 200 systems commissioned annually.

Since its inception, ZEME has been resolute in adopting the EPC route. The concept of "comprehensive responsibility" that underpins our EPC approach is deeply embedded within every aspect of our solutions and services.

System Design: The Art of Multi-Dimensional Balance

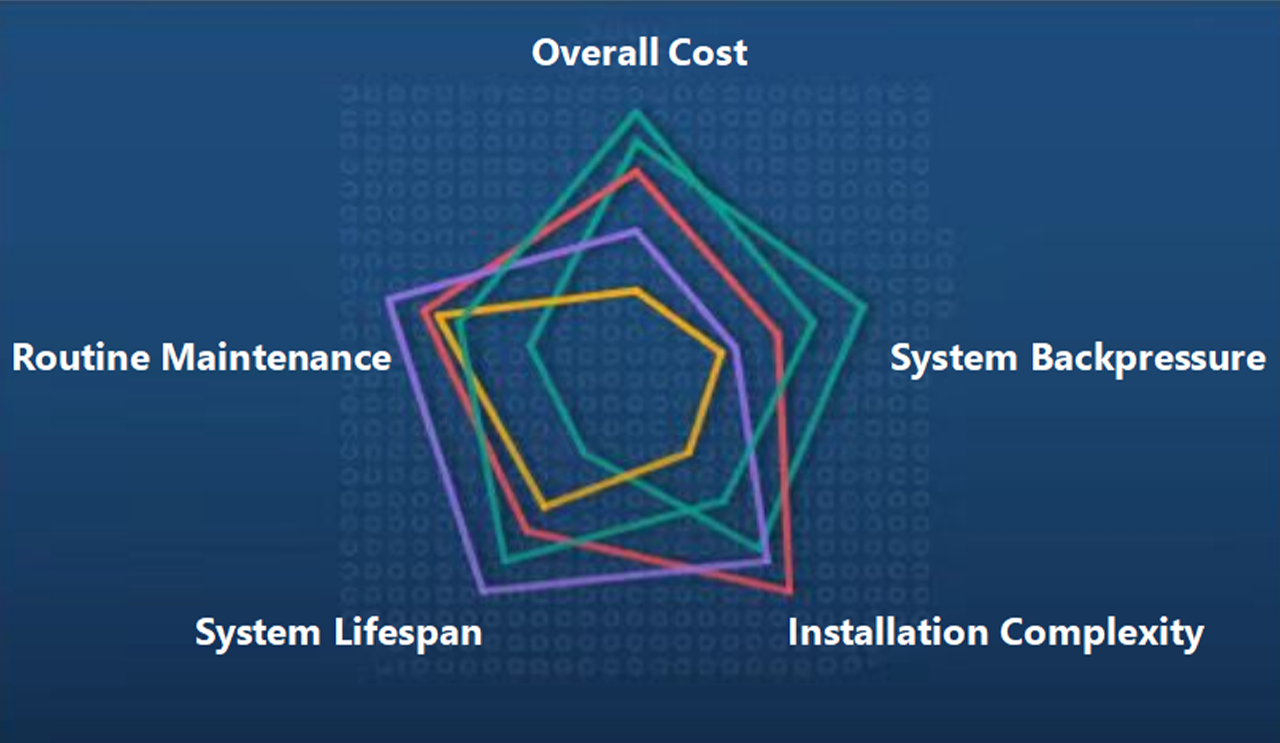

The essence of ZEME's system design lies in achieving multi-dimensional balance rather than relentlessly pursuing a single advantage. For instance, an obsessive focus on minimizing the scrubber tower size could result in higher electrical consumption and larger pipe diameters, while striving for reduced pump flow might require additional packing material. From the material and shape of the tower to the number and arrangement of internal nozzles, from equipment selection to pipe diameter determination, ZEME's system design aims to find the most suitable solution throughout the entire process. To us at ZEME, system design is not about being unconventional; it is about achieving a subtle equilibrium across multiple dimensions.

Retrofit Design – Tailored Solutions

ZEME's retrofit design fully embodies the principle of tailor-made solutions. By gaining a deep understanding of our clients' needs, ZEME can accurately match the unique requirements of each retrofit project, offering personalized solutions. From pipeline routing to cable arrangement, from the placement of scrubber towers to the layout of control cabinets, ZEME's retrofit design does not merely seek the shortest physical distances. Instead, we strive to understand the client's needs during installation, system operation, and daily maintenance.

For example, we consider the compatibility in time and space with other products undergoing simultaneous retrofitting. ZEME's diverse product line enables the company to design and implement other retrofit projects concurrently, avoiding unnecessary conflicts. In response to different installation and operational requirements, ZEME offers various tower configurations, providing clients with a wider range of options. To us at ZEME, retrofit design is not a one-size-fits-all approach, it is about creating tailored solutions.

Procurement and Manufacturing – A Robust Supply Chain for Efficient and Economical Support

ZEME's powerful supply chain system is one of the core competencies of our company's comprehensive general turnkey services. Through strategic cooperation with more than 800 high-quality suppliers globally, ZEME has built a comprehensive supply chain network that spans from international top-tier brands to on-site construction teams, and from advanced equipment to basic materials. Our efficient internal dispatch and management mechanisms further enhance the flexibility and responsiveness of the supply chain, ensuring stable supply even in the face of sudden changes such as unexpected shifts in shipping schedules. This allows us to meet our clients' most pressing needs effectively.

Installation and Commissioning – The Wisdom of Adapting to Challenges

ZEME's team has accumulated extensive experience in installation and commissioning projects around the globe. Whether it's solving unexpected problems in complex work environments or dealing with unforeseen challenges, we handle them with ease and confidence. From pipe collisions to flange deformations, and from loose wiring to damaged equipment, project managers and commissioning engineers may encounter various emergencies at any moment. However, their rich experience both domestically and internationally, combined with the resilience developed during the covid-19 when travel was difficult, has equipped them with the professional and psychological qualities to tackle challenges head-on.

Our project teams have innovatively proposed lifting the entire tower house onto the ship using a floating crane, enabling more prefabrication work to be completed before the vessel arrives at the yard. This approach significantly reduces the vessel's time in the yard for retrofitting. As a result, we were able to complete the retrofitting of an open-loop scrubber in just 18 days and a hybrid scrubber in 33 days, setting new benchmarks for efficiency.

After-Sales Service – A Commitment to Customer Centricity

Though the costs associated with after-sales services during warranty periods account for only 0.5% of operations, ZEME's after-sales service team remains diligent and proactive. From receiving notifications at 11 PM and arranging departures in Singapore by 1 AM, to developing remote monitoring systems that predict potential issues, ZEME's after-sales service goes beyond the commonly advertised "global network, 24/7 response." Instead, it prioritizes problem-solving at every turn. This customer-centric approach not only garners goodwill but also generates approximately 1,000 marine repair orders annually, contributing to revenue growth while informing product development and identifying new market needs.

As a global leader in Ship comprehensive general turnkey service provider, ZEME's competitive edge is not solely defined by technological innovation and product performance, but also by its profound understanding of and commitment to fulfilling customers' individualized requirements. Through exceptional design capabilities, tailored services, robust supply chain management, professional installation and commissioning teams, and a global after-sales service network, ZEME ensures precision and excellence at every step, exceeding expectations with each interaction.